Top Level > Clear Heatshrink 2:1 Ratio

25.4mm Diameter Clear Heatshrink Per 0.5m

£1.24

Clear Heatshrink 25.4mm Diameter x 0.5m

Supplied in 0.5 metre lengths

Shrink ratio 2:1

Shrinking temperature +80ºc

Made from polyolefin

Excellent flexibility and insulation

Excellent flame retardent properties

Temperature range -55°c to +125°c

UL approved

25.4mm is the internal diameter before shrinking

Purchase more than 1 length and it will be supplied in one continuous length

Weight per 0.5m length: 21grms

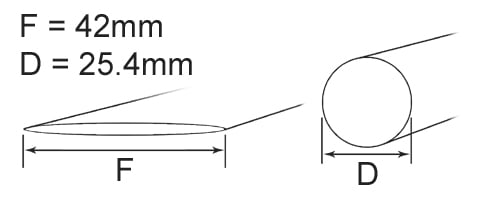

Heatshrink Measurements:

D = Diameter

F= Lay Flat Measurement

|

Inner Diameter mm |

Wall Thickness As Supplied mm |

Wall Thickness After Recovery mm |

|

1.0mm |

0.15 +/- 0.05 |

0.22 +/- 0.10 |

|

1.6mm |

0.15 +/- 0.05 |

0.28 +/- 0.10 |

|

2.4mm |

0.18 +/- 0.05 |

0.35 +/- 0.10 |

|

3.2mm |

0.18 +/- 0.05 |

0.40 +/- 0.10 |

|

4.8mm |

0.25 +/- 0.05 |

0.50 +/- 0.10 |

|

6.4mm |

0.28 +/- 0.05 |

0.55 +/- 0.10 |

|

9.5mm |

0.30 +/- 0.08 |

0.60 +/- 0.10 |

|

12.7mm |

0.30 +/- 0.08 |

0.60 +/- 0.10 |

|

19.1mm |

0.40 +/- 0.15 |

0.80 +/- 0.15 |

|

25.4mm |

0.55 +/- 0.15 |

0.90 +/- 0.15 |

|

38.1mm |

0.55 +/- 0.15 |

1.00 +/- 0.15 |

|

50.8mm |

0.60 +/- 0.18 |

1.00 +/- 0.15 |

|

76mm |

0.70 +/- 0.20 |

1.46 +/- 0.20 |

|

102mm |

0.70 +/- 0.20 |

1.46 +/- 0.20 |

|

127mm |

0.70 +/- 0.20 |

1.56 +/- 0.25 |

|

152mm |

0.80 +/- 0.25 |

1.66 +/- 0.25 |

|

178mm |

0.80 +/- 0.25 |

1.66 +/- 0.25 |

Technical Data |

||

|

Property

|

Test Method

|

Typical Data

|

|

Tensile Strength

|

ASTM D 2671

|

14MPa

|

|

Ultimate Elongation (%)

|

ASTM D 2671

|

450

|

|

Longitudinal Shrinkage (%)

|

UL 224

|

+/- 5

|

|

Heat Aging

Tensile Strength

Ultimate Elongation (%)

|

158¡É,

168hr

|

11MPa

300

|

|

Flammability

|

UL224 VW-1

|

Pass

|

|

Heat shock (250¡É,

4hrs)

|

ASTM D 2671

|

No cracking

|

|

Cold bend tests (-55¡É,

4hrs)

|

ASTM D 2671

|

No cracking

|

|

Dielectric Strength (kv/mm)

|

ASTM D 150

|

20

|

|

Volume Resistivity (ohm-cm)

|

ASTM D 876

|

1x1014

|

|

Copper Stability

|

UL224

|

Pass

|